The Tamper TRE-75 is a powerful and versatile construction tool that is essential for compacting soil and creating a solid foundation for a variety of construction projects. This article will explore the features, benefits and applications of the TRE-75 tamping rammer, and delve into its maintenance and safety precautions.

Features of tamping machine TRE-75

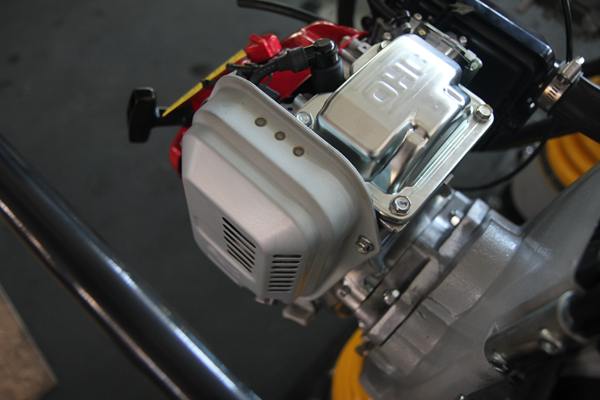

The compactor TRE-75 is designed to effectively compact soil in a variety of construction applications. It is equipped with a powerful engine that delivers high-impact compaction force, allowing it to effectively compact soil and create a stable foundation for structures such as roads, sidewalks, and foundations.

One of the main features of the tamping machine TRE-75 is its compact and ergonomic design, which allows it to be easily maneuvered and operated in tight spaces and challenging terrains. The machine is equipped with a durable and shock-resistant casing that protects its internal components from damage during operation, ensuring long-term reliability and performance.

The TRE-75 compactor also features a user-friendly control system that allows the operator to adjust compaction force and speed to meet the specific requirements of the job. This level of control allows for precise compaction and ensures the required soil density levels are achieved, providing a stable and durable foundation for construction projects.

Advantages of tamping hammer TRE-75

The tamping machine TRE-75 offers a series of advantages that make it an indispensable tool for construction professionals. One of the main advantages of this machine is its ability to achieve high compaction efficiency, thereby reducing the time and labor required to prepare the soil for construction. This results in cost savings and increased productivity on the job site.

Furthermore, the compactor TRE-75 is designed to provide consistent and even compaction, ensuring that the soil is evenly compacted over the entire surface. This helps prevent soil settling and uneven settlement, which can compromise the integrity of a construction project over time.

Furthermore, the tamping rammer TRE-75 is equipped with a low-maintenance engine and durable components, which contribute to its long service life and reliability. This minimizes downtime and maintenance costs, allowing construction professionals to focus on completing their projects efficiently and on schedule.

Application of tamping rammer TRE-75

The TRE-75 compactor is suitable for compacting soil required for a variety of construction applications, including road construction, pavement installation and foundation preparation. Its versatility and high-pressure strength make it ideal for compacting cohesive and granular soils in residential and commercial construction projects.

In road construction, the TRE-75 tamping machine is used to compact the roadbed and base layer to ensure a stable and durable foundation for the asphalt or concrete surface. This helps prevent settling and rutting, extending the life of the road and reducing the need for expensive repairs.

Likewise, in pavement installations, the TRE-75 tamper is used to compact the soil subgrade and base course before laying pavement materials. This creates a solid and uniform foundation for the pavement, thereby enhancing the pavement's load-bearing capacity and resistance to deformation under traffic loads.

During foundation preparation, the TRE-75 tamping machine was used to compact the soil beneath the building's foundation, ensuring that the soil could support the weight of the structure and minimize the risk of settlement or structural damage over time. This is critical to ensuring the long-term stability and integrity of the building.

Maintenance of tamping machine TRE-75

Proper maintenance is essential to ensure optimal performance and service life of your TRE-75 tamping machine. Regular maintenance tasks include checking and changing engine oil, air filter and spark plugs, as well as checking the fuel system and lubrication of moving parts as needed.

It is also important to inspect the tamping rammer TRE-75 for any signs of wear or damage, such as worn compaction shoes or damaged housing parts. Any worn or damaged parts should be replaced in time to prevent further damage to the machine and ensure safe and reliable operation of the machine.

Additionally, it is critical to follow the manufacturer's recommended maintenance schedule and procedures to ensure your TRE-75 tamping machine remains in optimal working order. This may include regular inspections and adjustments of the engine, clutch and compaction systems, as well as cleaning and lubricating the machine as needed.

Safety precautions when using the tamping machine TRE-75

When using the TRE-75 tamper, safety must be a priority to prevent accidents and injuries on the job site. Operators should receive appropriate training in the safe operation of the machine, including how to start and stop the engine, adjust compaction force, and operate the tamper in a variety of soil conditions.

Appropriate personal protective equipment such as goggles, gloves and steel-toed boots must be worn to protect against potential hazards such as flying debris, vibration and crushing injuries. In addition, operators should pay attention to their surroundings and ensure that the work area is clear of obstacles and other workers to prevent accidents.

Additionally, it is important to follow the manufacturer's guidelines for safe operation and maintenance of the TRE-75 Tamper Rammer, including avoiding overloading the machine, using the machine on stable, level ground, and maintaining a safe distance from the compaction area during operation.

In summary, the Tamper TRE-75 is a versatile and efficient construction tool that is essential for achieving high-quality soil compaction in a variety of construction applications. Its powerful engine, compact design and user-friendly controls make it a valuable asset for construction professionals looking to achieve a stable and durable foundation for their projects. By understanding its features, benefits, applications, maintenance requirements and safety precautions, operators can maximize the performance and service life of the TRE-75 while ensuring a safe and efficient work environment.

Post time: Jul-18-2024