In the world of construction and civil engineering, the importance of proper soil compaction cannot be overstated. One of the most effective tools for achieving this is the tamping rammer. This versatile piece of equipment is designed to compact soil, gravel, and other materials, ensuring a solid foundation for various construction projects. In this article, we will explore the tamping rammer in detail, discussing its features, applications, benefits, and maintenance tips.

What is a Tamping Rammer?

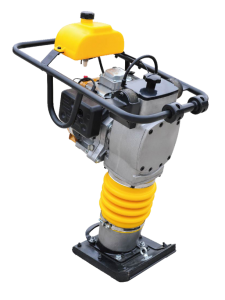

A tamping rammer, also known as a jumping jack or soil compactor, is a lightweight, portable machine used primarily for compacting soil in confined areas. It operates by delivering a series of rapid, vertical impacts to the ground, effectively compressing the material beneath it. The tamping rammer typically consists of a base plate, a powerful engine, and a foot or rammer that strikes the ground. The design allows for easy maneuverability, making it ideal for use in trenches, around foundations, and in other tight spaces where larger compaction equipment cannot operate.

Features of a Tamping Rammer

Tamping rammers come with several features that enhance their performance and usability:

1. Powerful Engine: Most tamping rammers are equipped with a gasoline or diesel engine that provides the necessary power to generate high-impact force. The engine's horsepower can vary, but it typically ranges from 3 to 5 HP.

2. Impact Force: The impact force of a tamping rammer is crucial for effective compaction. Most models can deliver an impact force of 2,000 to 3,000 pounds, allowing them to compact various types of soil and aggregate materials.

3. Weight: Tamping rammers are designed to be lightweight, usually weighing between 100 to 200 pounds. This makes them easy to transport and maneuver, especially in confined spaces.

4. Foot Size: The size of the foot or rammer varies among models, with typical dimensions ranging from 10 to 12 inches. A larger foot size can cover more area, while a smaller foot is better suited for tight spaces.

5. Vibration Control: Many modern tamping rammers come with vibration control features to reduce operator fatigue and improve comfort during extended use.

## Applications of Tamping Rammers

Tamping rammers are widely used in various construction applications, including:

1. Trenching: When digging trenches for utilities or foundations, tamping rammers are essential for compacting the soil backfill to prevent settling and ensure stability.

2. Paving: In road construction and paving projects, tamping rammers are used to compact the subgrade and base layers before laying asphalt or concrete.

3. Foundation Work: Tamping rammers are ideal for compacting soil around foundations, ensuring a solid base for structures and preventing future settling.

4. Landscaping: In landscaping projects, tamping rammers can be used to compact soil for pathways, patios, and other outdoor features.

5. Excavation Sites: On excavation sites, tamping rammers help compact soil in areas where larger equipment cannot reach, ensuring a stable working environment.

Benefits of Using a Tamping Rammer

The use of a tamping rammer offers several advantages:

1. Efficiency: Tamping rammers can compact soil quickly and effectively, reducing the time required for compaction compared to manual methods.

2. Versatility: With their ability to work in confined spaces, tamping rammers are suitable for a wide range of applications, making them a valuable addition to any construction fleet.

3. Improved Soil Stability: Proper compaction with a tamping rammer helps prevent soil erosion, settling, and other issues that can compromise the integrity of a structure.

4. Cost-Effective: Investing in a tamping rammer can save money in the long run by reducing labor costs and minimizing the risk of future repairs due to inadequate compaction.

5. Operator Safety: Modern tamping rammers are designed with safety features that protect operators from excessive vibration and fatigue, making them safer to use over extended periods.

Maintenance Tips for Tamping Rammers

To ensure optimal performance and longevity of a tamping rammer, regular maintenance is essential. Here are some tips:

1. Regular Inspections: Before each use, inspect the tamping rammer for any signs of wear or damage. Check the engine, foot, and base plate for any issues that may affect performance.

2. Clean After Use: After each job, clean the tamping rammer to remove dirt, debris, and other materials that may have accumulated during operation. This helps prevent rust and corrosion.

3. Change Oil Regularly: Follow the manufacturer's recommendations for oil changes to keep the engine running smoothly and efficiently.

4. Check Air Filter: A clean air filter is crucial for optimal engine performance. Inspect and replace the air filter as needed.

5. Store Properly: When not in use, store the tamping rammer in a dry, protected area to prevent damage from the elements.

Conclusion

The tamping rammer is an indispensable tool in the construction industry, providing efficient and effective soil compaction in a variety of applications. Its lightweight design, powerful engine, and versatility make it ideal for use in confined spaces, ensuring a solid foundation for any project. By understanding its features, applications, and maintenance requirements, construction professionals can maximize the benefits of this essential equipment, leading to safer and more successful projects. Whether you are a contractor, landscaper, or DIY enthusiast, investing in a tamping rammer can significantly enhance your compaction efforts and contribute to the overall success of your construction endeavors.

Post time: Dec-17-2024