The need for precision and efficiency in the ever-evolving construction industry has led to the development of advanced technologies that improve the quality of work. One such innovation is the laser scanning concrete paver, which has revolutionized the way concrete surfaces are leveled and finished. This article takes an in-depth look at the significance of this technology, particularly in terms of concrete paving and the smoothing machinery that accompanies it.

Learn about laser scanning concrete paver machinery

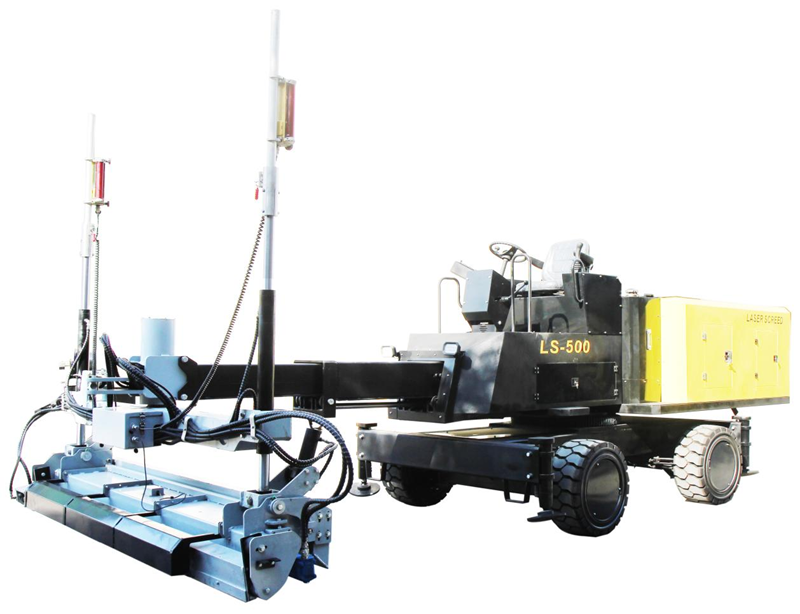

Laser scanning concrete pavers are designed to ensure that concrete surfaces are not only laid efficiently, but also meet the highest standards of smoothness and durability. The primary function of this machine is to facilitate the smoothing of concrete pavement, which is essential for both aesthetic and functional purposes. A smooth surface is essential to the longevity of a road as it reduces wear and tear on vehicles and improves driver safety.

Concrete screed machines utilize advanced laser scanning technology to assess the surface as concrete is poured. This technology allows real-time adjustments to be made, ensuring that the concrete is evenly distributed and perfectly leveled. The end result is a pavement that is not only aesthetically pleasing, but also structurally strong.

Main Features and Benefits

A major feature of the laser scanning concrete paver is its ability to perform mud lifting, vibration and road surface leveling during the paving construction process. This multi-functional capability significantly improves the flatness of the concrete surface and is very suitable for various applications such as bridge deck construction and township road projects.

Furthermore, the machine has been designed with flexibility in mind. The frame can be freely assembled and disassembled, allowing it to be adapted to road construction projects of varying widths. This versatility makes it a valuable asset for contractors working on different projects, as it can be easily modified to suit specific requirements.

Improve efficiency and quality

The combination of laser scanning technology and concrete paving machinery has significantly improved efficiency and quality. Traditional methods of concrete grading often rely on manual labor and guesswork, which can lead to inconsistencies and imperfections. However, with the precision provided by laser scanning, contractors can achieve a level of accuracy that was previously unattainable.

Additionally, using this advanced machinery can reduce the time required for concrete paving projects. By automating the grading process, contractors can complete jobs faster, allowing them to take on more projects and ultimately increase profitability. The improved quality of the finished product can also reduce subsequent repair and maintenance issues, further saving costs.

In conclusion

In conclusion, the advent of laser scanning concrete paving machines has revolutionized the concrete paving industry. By combining advanced technology with practical features, this machinery not only improves the smoothness and quality of concrete surfaces, but also increases the overall efficiency of construction projects. As the demand for high-quality pavement continues to grow, the importance of this innovative solution will only increase. For contractors looking to stay ahead in a competitive market, investing in laser scanning concrete paving smoothing machinery is a step toward achieving excellence in road construction.

Post time: Feb-10-2025