The construction industry has made significant advancements in technology over the years, and one innovation that has revolutionized the way concrete is leveled is the laser leveler LS-600. This state-of-the-art machine transforms the concrete pouring and leveling process, delivering unparalleled precision, efficiency and quality. In this article, we'll take an in-depth look at the features, benefits, and applications of the LS-600 laser screed and explore how it has become an indispensable tool for construction projects around the world.

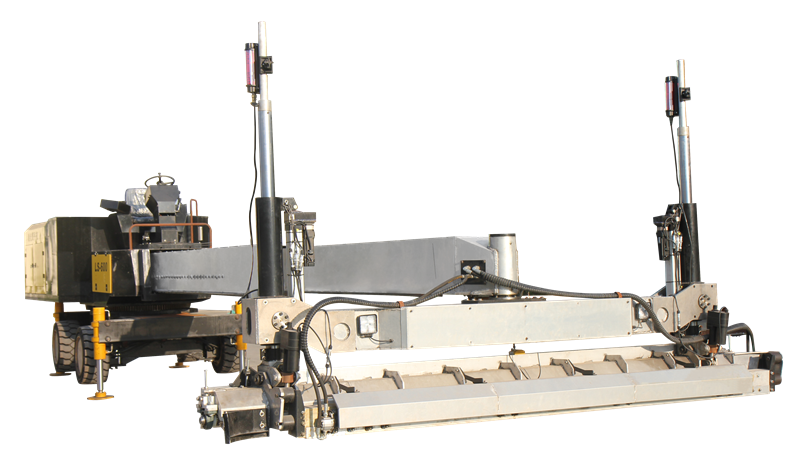

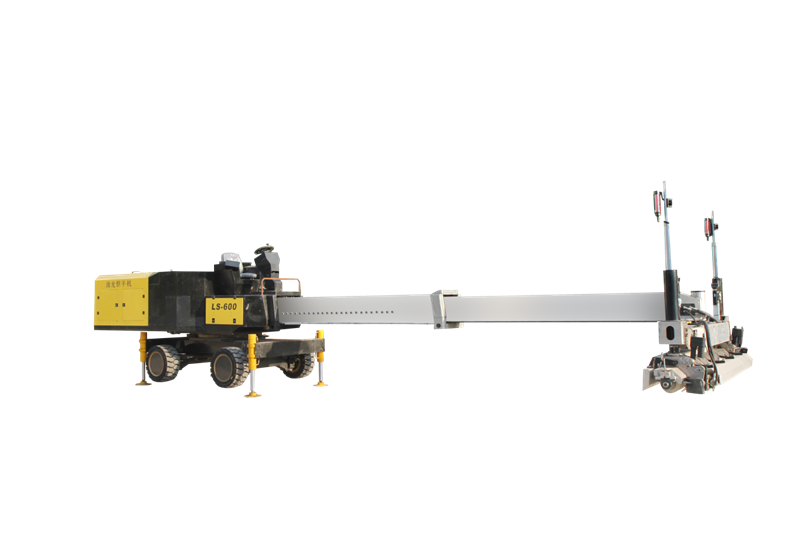

The Laser Leveler LS-600 is a cutting-edge device designed to simplify the process of leveling and finishing large concrete slabs. It utilizes advanced laser technology to ensure an extremely flat and level surface, making it ideal for a variety of applications including industrial floors, warehouse floors, commercial buildings and more. The machine is equipped with a laser guidance system that allows precise control of the height and slope of the concrete, resulting in superior flatness and consistency across the entire surface.

One of the main features of the laser leveling machine LS-600 is its high level of automation, which significantly reduces the need for manual labor and minimizes the margin of error. Operated by skilled technicians, the machine uses a laser control system to guide the screed head, ensuring concrete is leveled accurately and efficiently. This not only speeds up the construction process but also provides a finished product of superior quality, free of imperfections and fluctuations.

The laser leveler LS-600 is equipped with a powerful engine and hydraulic system, allowing it to cover large areas quickly and efficiently. Its high productivity makes it a valuable asset for construction projects with tight schedules, as it can significantly reduce the time and labor required for concrete pouring and leveling. Additionally, the machine is able to achieve superior flatness and leveling in a single pass, minimizing the need for additional finishing work and further speeding up construction time.

In addition to speed and accuracy, the LS-600 laser screed offers a host of other benefits that make it a top choice for contractors and construction professionals. Its ergonomic design and user-friendly controls ensure easy operation, while its sturdy construction and durable components make it a reliable and long-lasting investment. Additionally, the machine is capable of handling a variety of concrete mix designs and pouring conditions, making it versatile and adaptable to different project requirements.

The laser screed machine LS-600 is also known for its ability to improve the overall quality and durability of concrete floors. By achieving superior flatness and levelness, the machine helps eliminate common problems such as surface unevenness, curling and cracking that can compromise the structural integrity and functionality of concrete slabs. This, in turn, results in a more durable and resilient floor, reducing the need for costly repairs and maintenance in the future.

The applications of the laser screed machine LS-600 are diverse and cover all areas of the construction industry. From large industrial projects to small commercial developments, the machine's capabilities make it an indispensable tool for achieving superior concrete smoothness and level. Its ability to handle different types of concrete, including high-slump and low-slump mixtures, further extends its use to meet a wide range of construction requirements.

The laser screed machine LS-600 has also proven to be a game-changer in the field of concrete floors, especially in the context of modern warehouses and distribution facilities. These environments require extremely flat and level floors to accommodate automated material handling systems such as forklifts and conveyors. The machine’s ability to deliver the precise flatness required for this type of application makes it the solution of choice for ensuring efficient and safe warehouse operations.

In addition, the laser screed machine LS-600 makes a significant contribution to sustainable building practices by optimizing the use of materials and reducing waste. It achieves superior flatness and leveling with minimal manual intervention, minimizing the need for corrective actions and rework, resulting in more efficient use of resources. Additionally, the machine’s high productivity and speed help improve overall project efficiency, reducing energy consumption and environmental impact.

In summary, the laser screed machine LS-600 redefines the standards for concrete leveling and finishing in the construction industry. Its advanced technology, precision and efficiency make it an indispensable tool for achieving superior flatness and levelness in concrete slabs, while its versatility and durability solidify its position as the first choice for contractors and construction professionals. As construction practice continues to evolve, the laser screed machine LS-600 demonstrates the transformative power of innovation in shaping the built environment of the future.

Post time: Aug-08-2024