In construction, precision and efficiency are key. When it comes to concrete leveling, traditional methods can be time-consuming, laborious, and often result in an uneven surface. However, as technology advanced, the introduction of the laser leveler LS-500 revolutionized the way concrete is leveled, providing unparalleled accuracy and speed.

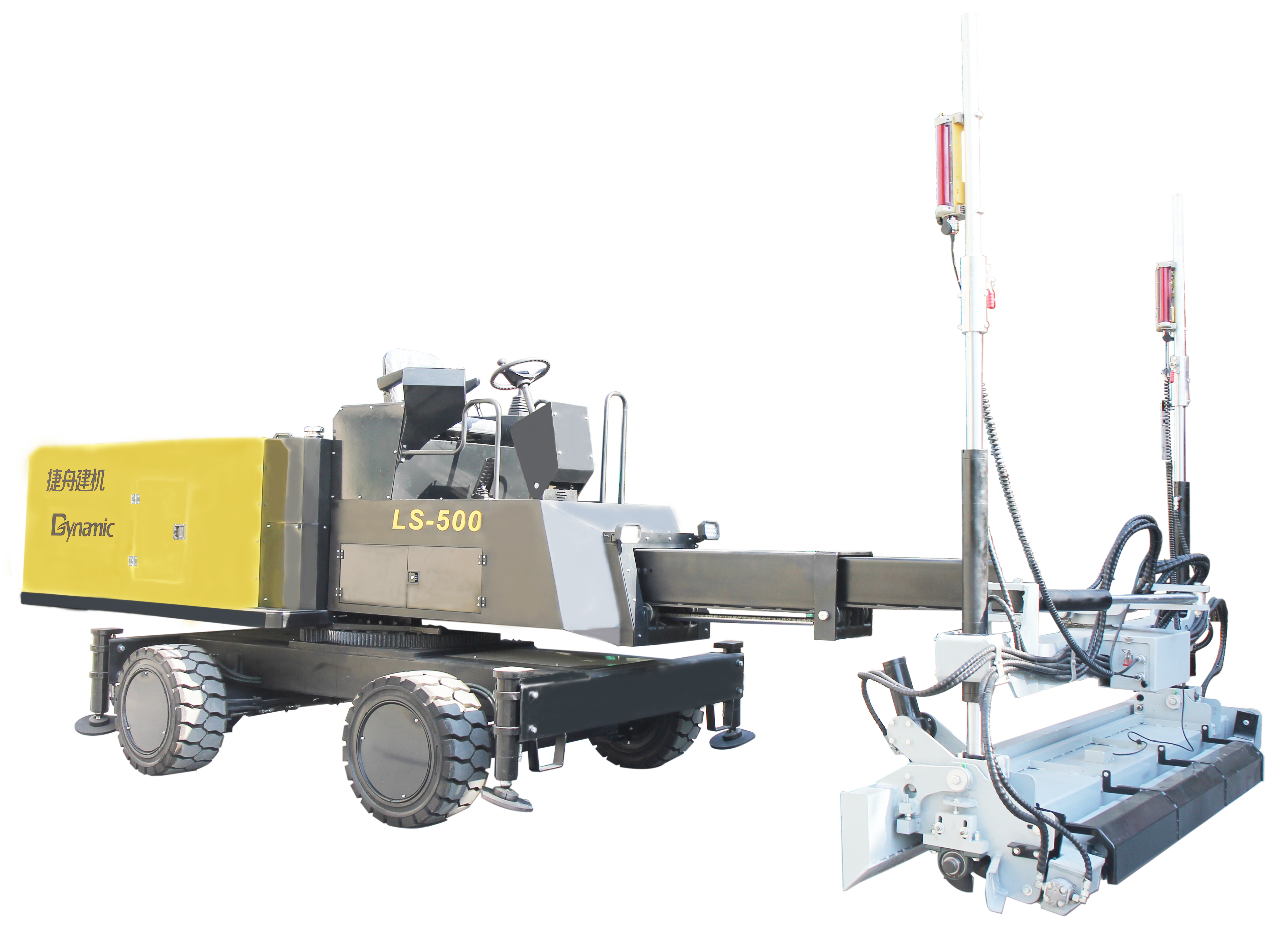

The Laser Leveler LS-500 is a state-of-the-art machine that uses laser technology to precisely level concrete surfaces. Unlike traditional methods such as manual leveling or using a traditional screed, the Laser Screed LS-500 automates the process to achieve a perfect finish and eliminate human error. This innovative machine has quickly become a staple in the construction industry, offering numerous benefits to contractors and owners alike.

One of the main advantages of the laser screed machine LS-500 is its ability to significantly reduce labor costs and construction time. Unlike traditional methods that require multiple workers to level concrete manually, the Laser Leveler LS-500 is operated by one skilled technician. The machine’s laser guidance system ensures the concrete is leveled with the highest precision, eliminating the need for constant rework and adjustments. This not only saves time but also reduces overall labor costs, making it a cost-effective solution for any size construction project.

Furthermore, the laser screed machine LS-500 offers unparalleled precision, ensuring that the concrete surface is perfectly level and flawless. The machine's laser technology can be monitored and adjusted in real time to achieve an even and smooth surface. This level of accuracy is critical, especially in projects where concrete surface quality is critical, such as industrial floors, warehouse facilities and commercial buildings. The laser screed machine LS-500 ensures that the final product meets the highest standards, enhancing the overall aesthetics and functionality of the concrete surface.

In addition to precision and efficiency, the laser leveler LS-500 also offers environmental advantages. By minimizing the need for manual labor and reducing the amount of wasted material reworked, the machine helps reduce the overall environmental impact of construction projects. With sustainability becoming an increasingly important consideration in the construction industry, the laser screed LS-500 offers a more environmentally friendly alternative to traditional concrete screeding methods.

Additionally, the laser leveler LS-500 is designed for ease of use, allowing operators to easily navigate and control the machine. Its intuitive interface and automated features make it easy for technicians to operate, reducing the need for extensive training and expertise. This ease of use not only increases overall productivity but also minimizes the risk of errors, ensuring a smooth and efficient concrete leveling process.

The versatility of the laser screed machine LS-500 also makes it a valuable asset for construction projects of varying sizes and complexity. Whether it is a small residential project or a large commercial development, the machine can be adjusted to meet the specific requirements of the job. Its ability to handle different types of concrete and adapt to a variety of structural designs makes it a valuable tool for contractors and builders looking for flexibility and adaptability on projects.

Additionally, the Laser Leveler LS-500 is designed with durability in mind, ensuring it can withstand the harsh conditions of a construction site. Its sturdy construction and reliable components make it a long-term investment for construction companies, minimizing the need for frequent maintenance and repairs.

In summary, the LS-500 Laser Leveler changes the way concrete is leveled, delivering unparalleled precision, efficiency and versatility. Its advanced laser technology, cost-effective operation and environmental benefits make it an indispensable tool for construction projects around the world. As the demand for high-quality concrete surfaces continues to grow, the laser screed machine LS-500 remains at the forefront of innovation, setting new standards for concrete leveling in the construction industry.

Post time: Feb-23-2024