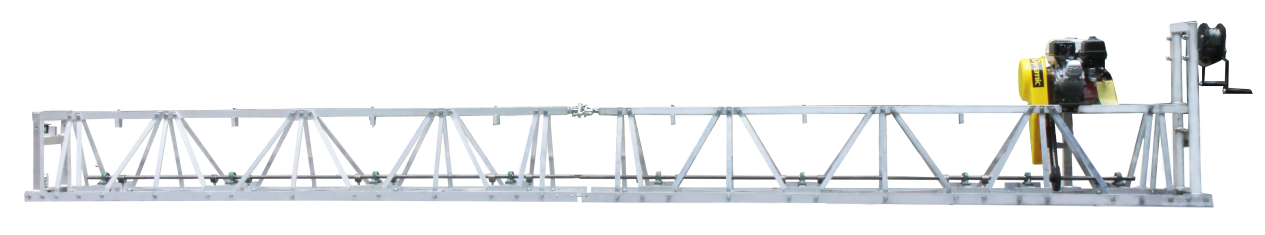

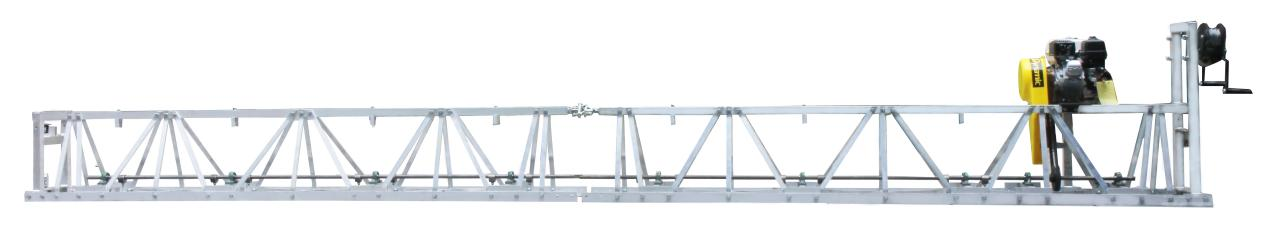

As the construction industry continues to evolve, the demand for precision and efficiency in building processes has never been higher. Among the innovative tools that have emerged to meet these demands is the Concrete Machine Vibrating Beam. This advanced piece of equipment is set to revolutionize the way concrete is poured and finished in 2025, offering contractors and builders a reliable solution for achieving superior results.

Understanding the Concrete Machine Vibrating Beam

The Concrete Machine Vibrating Beam is a specialized tool designed to enhance the quality of concrete surfaces. It operates by utilizing vibration technology to ensure that concrete is evenly distributed and compacted during the pouring process. This tool is particularly beneficial for large-scale construction projects, where precision and uniformity are critical.

The vibrating beam works by creating a controlled vibration that helps to eliminate air pockets and voids within the concrete mix. This not only improves the overall strength and durability of the concrete but also enhances its aesthetic appeal. The result is a smooth, level surface that meets the high standards expected in modern construction.

Key Features of the Concrete Machine Vibrating Beam

1. Precision Engineering: The Concrete Machine Vibrating Beam is engineered with precision in mind. Its design allows for accurate leveling and finishing of concrete surfaces, ensuring that every project meets the required specifications.

2. Adjustable Vibration Settings: One of the standout features of this tool is its adjustable vibration settings. Operators can customize the intensity of the vibrations based on the specific requirements of the project, allowing for greater control over the finishing process.

3. Lightweight and Portable: Despite its robust capabilities, the vibrating beam is lightweight and easy to transport. This portability makes it an ideal choice for contractors who need to move between job sites frequently.

4. Durable Construction: Built to withstand the rigors of construction work, the Concrete Machine Vibrating Beam is made from high-quality materials that ensure longevity and reliability. This durability translates to lower maintenance costs and increased productivity.

5. User-Friendly Interface: The tool features an intuitive interface that allows operators to quickly learn how to use it effectively. This ease of use reduces the training time required for new employees, enabling teams to get to work faster.

Benefits of Using the Concrete Machine Vibrating Beam

The adoption of the Concrete Machine Vibrating Beam in construction projects offers numerous benefits:

Enhanced Quality of Work

The primary advantage of using a vibrating beam is the significant improvement in the quality of the finished concrete surface. The controlled vibrations help to achieve a denser and more uniform mix, resulting in fewer defects and a more aesthetically pleasing finish.

Increased Efficiency

Time is money in the construction industry, and the Concrete Machine Vibrating Beam helps to streamline the pouring and finishing process. By reducing the need for manual labor and minimizing the risk of errors, contractors can complete projects more quickly and efficiently.

Cost-Effectiveness

While the initial investment in a Concrete Machine Vibrating Beam may be higher than traditional tools, the long-term savings are substantial. The enhanced quality of work reduces the likelihood of costly repairs and rework, ultimately leading to a better return on investment.

Versatility

This tool is not limited to a specific type of project. Whether it’s residential, commercial, or industrial construction, the Concrete Machine Vibrating Beam can be utilized across various applications. Its versatility makes it a valuable addition to any contractor’s toolkit.

The Future of Construction with the Concrete Machine Vibrating Beam

As we move into 2024, the construction industry is poised for further advancements in technology and equipment. The Concrete Machine Vibrating Beam represents a significant step forward in achieving precision and efficiency in concrete work. With its innovative features and numerous benefits, it is likely to become a staple in construction projects worldwide.

Contractors who embrace this technology will not only improve the quality of their work but also enhance their competitiveness in the market. As clients increasingly demand higher standards and faster turnaround times, the ability to deliver exceptional results with the help of advanced tools like the Concrete Machine Vibrating Beam will be crucial.

Conclusion

In conclusion, the Concrete Machine Vibrating Beam is a precision construction tool that is set to make a significant impact in 2025. Its ability to enhance the quality of concrete surfaces, increase efficiency, and provide cost-effective solutions makes it an essential tool for modern construction projects. As the industry continues to evolve, embracing innovative technologies like the vibrating beam will be key to staying ahead of the competition and meeting the ever-growing demands of clients. For contractors looking to elevate their work and ensure the highest standards of quality, investing in a Concrete Machine Vibrating Beam is a decision that will pay dividends for years to come.

Post time: Apr-17-2025